Smart factory concept and Industry 4.0

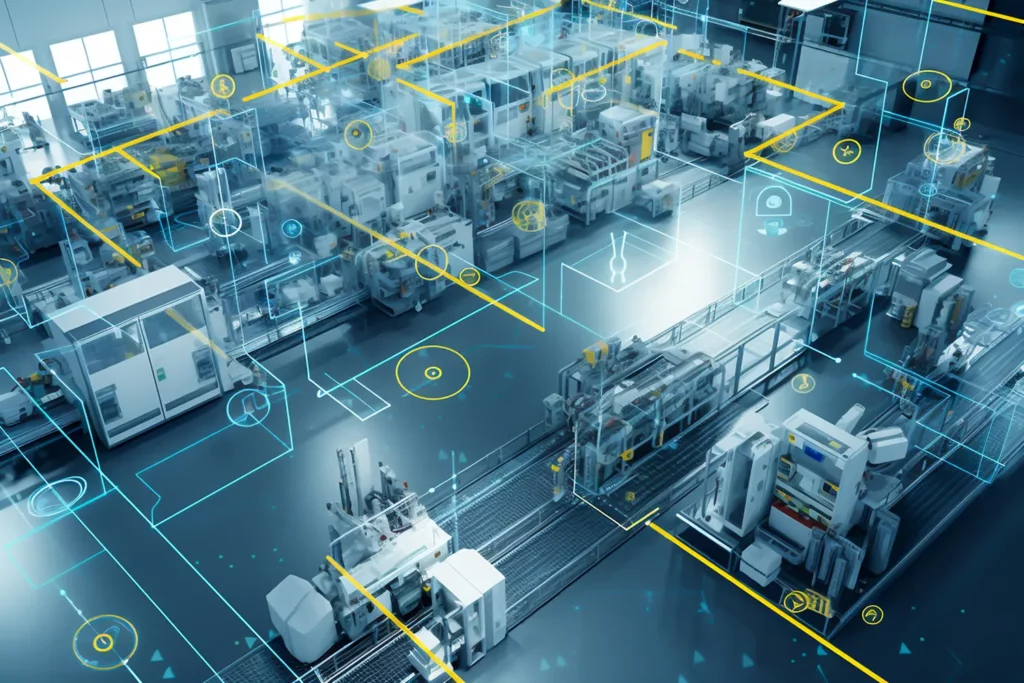

The Smart Factory Concept and Industry 4.0: Revolutionizing Manufacturing

The manufacturing industry is undergoing a seismic transformation, driven by the advent of the smart factory concept and Industry 4.0. These revolutionary developments are reshaping how goods are produced, enabling manufacturers to achieve unprecedented levels of efficiency, productivity, and flexibility. But what exactly do these terms mean, and how are they shaping the future of manufacturing? Let’s delve deeper.

Understanding the Smart Factory Concept

A smart factory represents the pinnacle of modern manufacturing—an interconnected and highly automated environment where machines, devices, and systems communicate seamlessly to optimize production processes. Powered by technologies like the Internet of Things (IoT), artificial intelligence (AI), big data, and robotics, smart factories are designed to:

- Enhance Efficiency: By collecting and analyzing real-time data, smart factories identify bottlenecks and implement solutions instantly.

- Improve Quality: Advanced monitoring systems ensure consistent quality, reducing defects and waste.

- Foster Flexibility: Smart factories can quickly adapt to changes in production demands or specifications.

The smart factory is a cornerstone of Industry 4.0, often dubbed the “Fourth Industrial Revolution.”

What is Industry 4.0?

Industry 4.0 refers to the integration of cutting-edge digital technologies into manufacturing. It builds on earlier industrial revolutions—mechanization, mass production, and automation—to usher in an era defined by smart systems and interconnected processes.

Key features of Industry 4.0 include:

- IoT Integration: Machines and devices equipped with sensors communicate and exchange data autonomously.

- Big Data Analytics: Insights derived from massive data sets optimize production processes and inform decision-making.

- AI and Machine Learning: These technologies enable predictive maintenance, reducing downtime and extending equipment life.

- Cyber-Physical Systems: A fusion of physical machinery and digital systems allows real-time interaction between production lines and management systems.

Benefits of Embracing Smart Factories and Industry 4.0

The adoption of smart factories and Industry 4.0 offers a multitude of benefits, including:

- Cost Efficiency: Automation and predictive analytics significantly lower operational costs.

- Sustainability: Optimized processes reduce energy consumption and waste, supporting green manufacturing initiatives.

- Enhanced Competitiveness: Faster production cycles and higher quality output give businesses a competitive edge.

- Customization: Manufacturers can produce customized products at scale, catering to evolving consumer preferences.

Challenges and Considerations

While the advantages are compelling, transitioning to smart factories comes with challenges such as:

- High Initial Investment: Implementing advanced technologies requires significant capital.

- Cybersecurity Risks: Increased connectivity exposes systems to potential cyber threats.

- Skill Gaps: Workers need to be trained in using and managing sophisticated systems.

The Future of Smart Manufacturing

As more industries adopt the smart factory concept and Industry 4.0 technologies, the manufacturing landscape will continue to evolve. Future advancements may include:

- Greater integration of 5G connectivity for faster and more reliable communication between devices.

- Increased use of blockchain for secure and transparent supply chain management.

- Expansion of digital twins, virtual replicas of physical systems used for real-time monitoring and optimization.

Conclusion

The smart factory concept and Industry 4.0 represent the next frontier in manufacturing, offering unparalleled opportunities for growth, innovation, and sustainability. By leveraging these technologies, businesses can stay ahead in an increasingly competitive global market. As we move further into the era of digital transformation, the question isn’t whether to adopt these advancements but how quickly they can be implemented to drive success.